Хората често се обръщат към потребителския опит, когато избиратМашина за челюстна трошачка.

- Отзивите подчертават какЧасти за трошачкакатоВисококачествена манганова стоманаиДвигателни пръти за трошачкаиздържат на трудни задачи.

- Потребителите споделят съвети за поддръжкаЧасти за челюстна трошачка.

- Положителните истории за следпродажбената помощ могат да накарат купувачите да се чувстват по-уверени.

Ключови изводи

- Потребителските отзиви разкриват какчелюстни трошачкиизпълняват в реални задачи, помагайки на купувачите да разберат издръжливостта, лекотата на използване и ефективността, преди да купят.

- Редовната поддръжка и навременната подмяна на части, споделени от потребителите, поддържатмашини, работещи по-дългои да намалят скъпите ремонти.

- Силната поддръжка на клиенти и бързата доставка на резервни части, похвалени от потребителите, повишават доверието и минимизират времето за престой.

Защо потребителските отзиви са важни за челюстните трошачки

Анализи на реалната производителност

Потребителските отзиви дават ясна представа за това как работи челюстната трошачка в ежедневните операции. Хората споделят истории за раздробяване на бетон, добив на скали или обработка на скрап. В тези отзиви често се споменава дали машината отговаря или надминава очакванията им. Много купувачи търсят обратна връзка за неща като производителност, размер на подавания материал и качество на крайния продукт. Те искат да знаят дали машината може да се справи с трудни задачи или дали има затруднения с определени материали.

Експертите от индустрията препоръчват да посетите дилърски обекти и да разговаряте с настоящи потребители. Това помага на купувачите да видят как работи оборудването и дали дилърът предлага добра поддръжка.

Обратна връзка за надеждност и издръжливост

Купувачите се доверяват на потребителските отзиви, за да научат за надеждността и издръжливостта. Някои потребители говорят за машини със здрави стоманени рамки или специални функции, които издържат по-дълго и се нуждаят от по-малко обслужване. Други сравняват марки и модели, като посочват кои от тях имат по-малко повреди или по-бързи ремонти.

- Потребителите често споменават:

- Колко дълго издържат челюстните плочи и другите части

- Ако машината продължава да работи без много спирания

- Колко лесно е да се сдобиете с резервни части

Таблица с често срещани отзиви може да изглежда така:

| Функция | Коментари на потребителите |

|---|---|

| Стоманена рамка | „Много здрав, издържа години“ |

| Модулен дизайн | „Лесен за ремонт“ |

| Резервни части | „Бърза доставка, по-малко време за престой“ |

Опит в поддръжката и ремонта

Историите за поддръжка помагат на купувачите да избегнат изненади. Много потребители говорят за необходимостта от подмяначелюстни плочи, превключващи пластини или лагери. Някои казват, че е трудно да се достигне до определени части, което забавя ремонтите. Други предупреждават за прегряване на лагери или течове на масло.

- Често срещани предизвикателства включват:

- Чести подмени на части

- Запушени камери от натрупване на материал

- Проблеми с вибрациите или стартирането

Рутинните проверки и навременните ремонти поддържат челюстната трошачка безпроблемно работеща. Хората често споделят съвети как да направят поддръжката по-лесна и по-евтина.

Ключови теми в потребителския опит на челюстната трошачка

Лекота на използване и работа

Много потребители говорят за това колко лесно е да се управлява челюстна трошачка. Операторите харесват машини с прости контроли и ясни дисплеи. В строителството хората често работят в тесни пространства или местят оборудване от обект на обект. Те искат машини, които са компактни и лесни за настройване. Някои модели имат безжично управление, което помага на операторите да работят от безопасно разстояние. Минните екипи търсят машини със силни диагностични системи. Те им помагат да следят производителността, дори в отдалечени райони.

Забележка: Удобният за потребителя интерфейс може да спести време и да намали грешките, особено за новите оператори.

Издръжливост при тежки условия

Издръжливостта е най-важна, когато работата стане трудна. В минното дело,челюстните трошачки се изправят трудноабразивни скали всеки ден. Двойно превключващите конструкции и здравите стоманени рамки помагат на тези машини да издържат по-дълго. Строителните екипи използват челюстни трошачки за разбиване на бетон и асфалт. Те се нуждаят от машини, които могат да обработват различни материали, без да се износват бързо.

Изследователите са тествали как тези машини се представят под напрежение. Те разглеждат неща като потребление на енергия, износване на частите и колко добре машината се справя с големи товари. Въпреки че повечето доклади идват от лаборатории, а не от потребители, тези проучвания показват, че изборът на дизайн оказва голямо влияние върху това колко дълго трае машината.

Изисквания и разходи за поддръжка

Поддръжката е важна тема в потребителските отзиви. Хората искат да знаят колко струва поддържането на челюстна трошачка в експлоатация. Новите машини обикновено струват по-малко за поддръжка. Те често се предлагат с гаранции и интелигентни функции, които предвиждат кога са необходими ремонти. Употребяваните машини могат да струват много повече, особено ако се нуждаят от спешни ремонти.

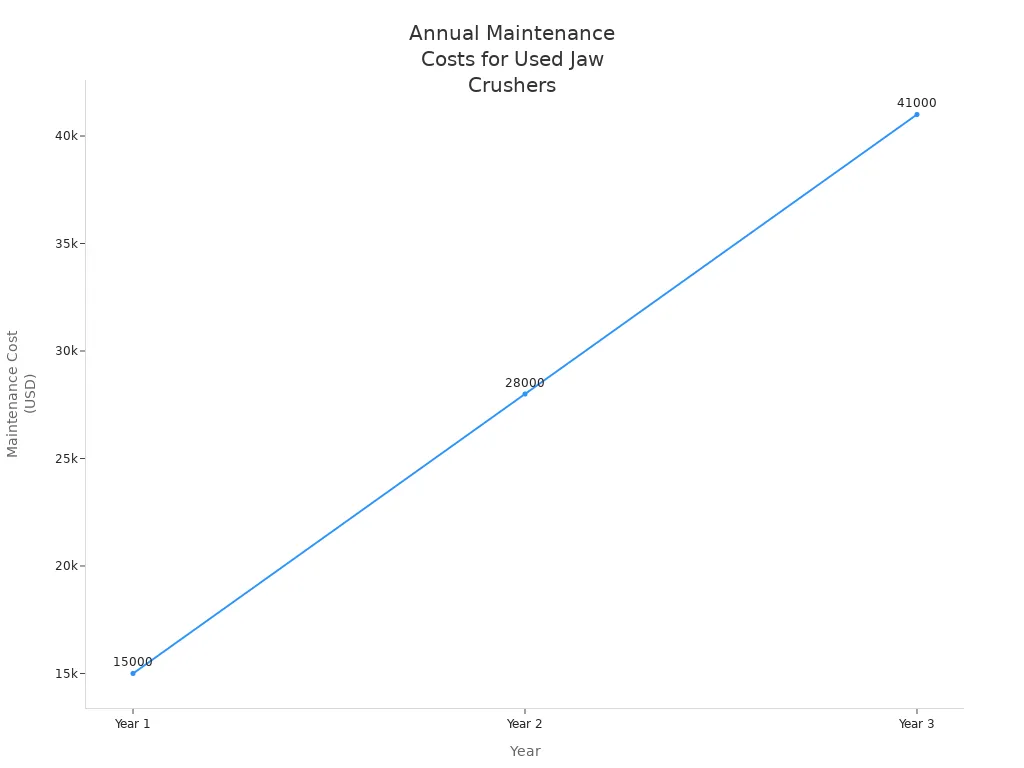

Ето таблица, показваща средните годишни разходи за поддръжка:

| Тип оборудване | Средни годишни разходи за поддръжка | Прогресия на разходите за поддръжка (употребявано оборудване) | Допълнителни бележки |

|---|---|---|---|

| Нови челюстни трошачки | Приблизително 8 000 долара | Няма данни | Включва 5-годишна гаранция и функции за прогнозна поддръжка |

| Употребявани челюстни трошачки | Приблизително 21 000 долара | Година 1: 15 000 долара Година 2: 28 000 долара (повреда на лагер) Година 3: $41 000 (подмяна на ексцентричен вал) | 68% от ремонтираните жилища изискват спешни ремонти на стойност над 20 000 долара в рамките на 6 месеца |

Съвет: Редовните проверки и навременната подмяна на части могат да помогнат за намаляване на дългосрочните разходи.

Оперативна ефективност и резултати

Потребителите често се фокусират върху това колко материал може да обработи една челюстна трошачка. Производителността, измерена в тонове на час (TPH), е ключово число. Операторите регулират настройки като ъгъла на захвата и междината на изпускане, за да получат най-добрия резултат. Видът материал също има значение. Твърдите скали забавят процеса и износват частите по-бързо.

Ето някои неща, които потребителите споменават, когато говорят за ефективност:

- Производителност (TPH) и как тя се променя с размера на машината

- Регулиране на настройките за контрол на размера и производителността на продукта

- Поддържане на дневна, седмична и месечна поддръжка

- Следене за износване на челюстните пластини и подмяната им навреме

- Модернизиране на части за по-добро използване на мощността и по-малко време на престой

- Използване на сензори и данни за ранно откриване на проблеми

- Обучение на оператори, за да извлекат максимума от всяка машина

Квалифицираният оператор може да окаже голямо влияние върху това колко добре работи машината.

Поддръжка и обслужване на клиенти

Доброто обслужване на клиентите се откроява в много отзиви. Хората хвалят компаниите, които отговарят бързо на въпроси и предлагат полезни съвети. Бързата доставка на резервни части и ясните гаранционни политики карат потребителите да се чувстват сигурни. Някои марки, като EAGLE Crusher и Allpack, получават високи оценки за следпродажбеното си обслужване.

Ето един бърз преглед на това, което харесват потребителите:

- Бърза и ясна комуникация, често в рамките на 24 часа

- Персонал, който познава машините и дава полезни съвети

- Бързо решаване на проблеми и активно проследяване

- Навременна доставка и лесни гаранционни рекламации

- Безплатна доставка за големи поръчки и гъвкави планове за плащане

| Марка | Акценти на следпродажбеното обслужване |

|---|---|

| Трошачка EAGLE | Иновативни машини, висококачествено обслужване, надежден персонал |

| Олпак | Ориентация към клиента, бърза доставка, строг контрол на качеството |

| Кийстрак | Добра комуникация, персонализирани решения |

| ТЕСАБ | Честно сътрудничество, висока удовлетвореност |

| Сандвик | Услуги за обучение, силни партньорства |

| ТЕРЕКС | Пълна поддръжка за машини, части и сервиз |

| Супериор | Ефективни решения, почтеност, добро сътрудничество |

| Хюит Робинс | Силна техническа поддръжка, глобален обхват |

Забележка: Надеждната поддръжка може да намали времето за престой и да помогне на потребителите да извлекат максимума от своята челюстна трошачка.

Как да тълкуваме потребителските отзиви за челюстна трошачка

Разграничаване на истинска и предубедена обратна връзка

Не всеки отзив разказва цялата история. Някои отзиви звучат твърде добре, за да са истина. Други изглеждат несправедливо негативни. Хората могат да разпознаят истинската обратна връзка, като търсят подробности. Реалните потребители често споделят конкретни факти за своя опит. Те могат да споменат вида материал, който са смачкали, или колко дълго са използвали машината. Отзиви, които използват неясни думи като „невероятно“ или „ужасно“ без примери, може да не са от голяма полза.

Ето няколко съвета как да разпознаете честни отзиви:

- Потърсете отзиви със снимки или видеоклипове.

- Проверете дали рецензентът обяснява какво му е харесало или не.

- Обърнете внимание дали рецензията говори както за добри, така и за лоши страни.

Съвет: Ако даден отзив повтаря едни и същи фрази или звучи като реклама, може да не е истински.

Оценка на съответствието с вашите нужди

Всяка работа е различна. Отзив, който помага на един човек, може да не е от полза за друг. Хората трябва да помислят за собствените си нужди, преди да се доверят на отзив. Например, потребител, който работи в минното дело, може да се нуждае от по-силенМашина за челюстна трошачкаотколкото някой, който троши бетон на малък обект.

Задайте си тези въпроси, когато четете отзиви:

- Рецензентът използва ли машината за същия вид работа?

- Подходящ ли е размерът на машината за вашия проект?

- Споменават липроблеми или характеристикитова има значение за теб?

Таблица може да ви помогне да сравните вашите нужди с прегледа:

| Вашата нужда | Пример за преглед | Съвпадение? |

|---|---|---|

| Смачкване на твърда скала | „Справя се с гранит без проблеми“ | ✅ |

| Лесно преместване между сайтове | „Лек, лесен за транспортиране“ | ✅ |

| Ниска поддръжка | „Изисква честа смяна на части“ | ❌ |

Забележка: Отзивите, които отговарят на вашия стил на работа и нужди, дават най-добрите съвети.

Търсене на последователни модели

Едно ревю не разказва цялата история. Хората трябва да прочетат няколко ревюта, за да открият модели. Ако много потребители споменават един и същ проблем, това може да е реален проблем. Ако повечето ревюта хвалят една и съща функция, това вероятно е предимство.

Потърсете тези модели:

- Много потребители говорят за счупване на една и съща част.

- Няколко отзива споменават бързото обслужване на клиентите.

- Повечето хора са съгласни, че контролите са лесни.

Когато в рецензиите се появи някаква закономерност, тя често сочи към реална сила или слабост.

Вземане на решение с челюстна трошачка - потребителски мнения

Съответствие на потребителското изживяване с вашите приоритети

Всяка компания има свои собствени цели при избора на оборудване. Някои искат най-висока производителност, докато други се интересуват повече от безопасността или лесната поддръжка. Потребителският опит може да помогне за съчетаването на тези нужди с правилната челюстна трошачка. Например, ако екипът иска по-малко време на престой, може да потърси отзиви, които споменават бърза смяна на части или лесни ремонти. Ако безопасността е основен приоритет, истории за ясни аварийни спирания или добро обучение се открояват.

Ето някои интелигентни начини, по които компаниите съобразяват потребителската обратна връзка със своите приоритети:

- Те настройват настройките на трошачката въз основа на вида материал и размера, който искат.

- Те планират редовни проверки исменете износените частипреди да започнат проблемите.

- Те следят производствените показатели и следят скоростта на подаване.

- Те използват съвети за отстраняване на неизправности от други потребители, за да отстранят проблемите бързо.

- Те спазват мерките за безопасност и обучават работниците на планове за действие при извънредни ситуации.

- Те използват обратна връзка и данни, за да се усъвършенстват непрекъснато.

- Те научават за нови технологии и най-добри практики от експерти и други потребители.

Компаниите, които използват тези стъпки, често постигат по-добри резултати и по-малко изненади.

Комбиниране на отзиви с технически данни

Потребителските отзиви разказват реални истории, но техническите данни дават суровите факти. Когато компаниите комбинират и двете, те вземат по-добри решения. Например, в един отзив може да се посочва, че челюстната трошачка работи тихо, но спецификациите показват точното ниво на шум. В Северна Америка много компании вече използват интелигентни системи със сензори и машинно обучение. Тези инструменти помагат за прогнозиране кога е необходима поддръжка и поддържат машините в безопасна работа. Модулните конструкции и екологичните характеристики също помагат за постигане на целите на компанията за безопасност и околна среда.

Една проста таблица може да помогне за сравняване на това, което казват потребителите, с това, което показват данните:

| Обратна връзка от потребителите | Технически данни |

|---|---|

| „Лесен за поддръжка“ | Интервал на поддръжка: 500 часа |

| „Справя се с твърди скали“ | Максимален размер на подаване: 24 инча |

| „Ниска консумация на енергия“ | Мощност: 75 kW |

Като разгледат както отзивите, така и спецификациите, компаниите могат да изберат челюстна трошачка, която наистина отговаря на техните нужди.

Потребителският опит помага на купувачите да видят отвъд техническите брошури. Те научават за поддръжката, потреблението на енергия и формата на продукта. Таблицата по-долу показва какво е най-важно при избора на оборудване. Чрез комбиниране на реална обратна връзка с технически данни, компаниите правят по-интелигентен избор.

| Ключов извод | Описание |

|---|---|

| Поддръжка | Челюстите се износватот абразивни материали като желязна руда. Необходима е редовна подмяна или ремонт. |

| Консумация на енергия | Трошачките използват много енергия, особено при твърди материали. Ефективността зависи от размера и скоростта на подаване. |

| Форма и еднородност на продукта | Натрошеният продукт често има неправилни форми, което може да повлияе на по-късните етапи на обработка. |

ЧЗВ

Как потребителските отзиви помагат при избора на челюстна трошачка?

Потребителските отзиви показват реални проблеми и успехи. Те помагат на купувачите да видят какво работи в ежедневната употреба, а не само това, което пише в брошурата.

Какво трябва да търсят купувачите в потребителските отзиви за челюстна трошачка?

Купувачите трябва да проверят за коментари относно поддръжката, живота на частите и обслужването на клиентите. Модели вотзивите често посочваткъм реални силни или слаби страни.

Може ли потребителското изживяване да замести техническите данни?

Потребителското изживяване добавя стойност, но не може да замести техническите данни. Умните купувачи използват и двете, за да направят най-добрия избор за своите нужди.

Време на публикуване: 14 август 2025 г.